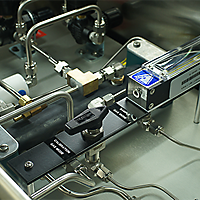

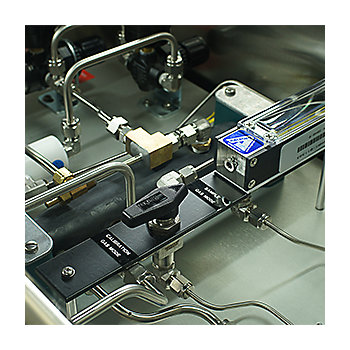

Sample Conditioning Packages

Sample conditioning for reliable oxygen gas-phase measurement

Neutronics Sample Conditioning Packages are designed to ensure that our oxygen sensors always have a clean and dry sample gas stream. Process conditions that include solvents, corrosive chemicals, and temperature extremes present significant challenges. To deliver accurate and reliable gas measurement, sensors require a sample that is free of contaminants. Sample conditioning systems built to withstand harsh processing conditions and efficiently remove damaging contaminants from the sample stream are critical to delivering reliable continuous-duty low-maintenance gas monitoring.

Neutronics provides systems for use in processes with continuous or varying pressure, ranging from high vacuum to 2,000 PSI. Three standard sample extraction methods are used to get the sample gas to the sensor. A continuous positive pressure drive system is used for process pressures above 5 PSI. A pneumatically driven intrinsically safe aspirator is used for pressures closer to atmospheric, and a vacuum pump drive system is used for processes running at high vacuum or if compressed gas consumption is a concern.

An industry leader in process gas sample conditioning, we have designed and installed thousands of systems in industrial manufacturing plants. Starting with a focus on applications in the chemical industry back in 1978, our markets have expanded to include applications in a variety of industries ranging from paints/coatings, pharmaceuticals, and industrial gases to power generation, metals production and food & beverage.

- Continuous positive pressure within the process vessel or system provides the force that pushes the sample gas from the process to the sensor.

- A pneumatically-driven aspirator is used to extract the sample gas from the process

- When compressed gas is not available or when the process is running at high vacuum, a diaphragm vacuum pump is used to draw the sample gas stream to the sensor